Today’s Jäger Gummi und Kunststoff GmbH represents the origin and core business of the JÄGER Group. As a technical distributor, manufacturing specialist and development partner in rubber, silicone and plastics, we have been providing our customers in a wide range of industries with advice and support for more than 80 years.

With the help of our decentralized sales structure at eight locations in Germany, we combine an average of more than 200 years of experience and application knowledge in elastomer and plastic per location and provide our customers with competent and comprehensive advice on site.

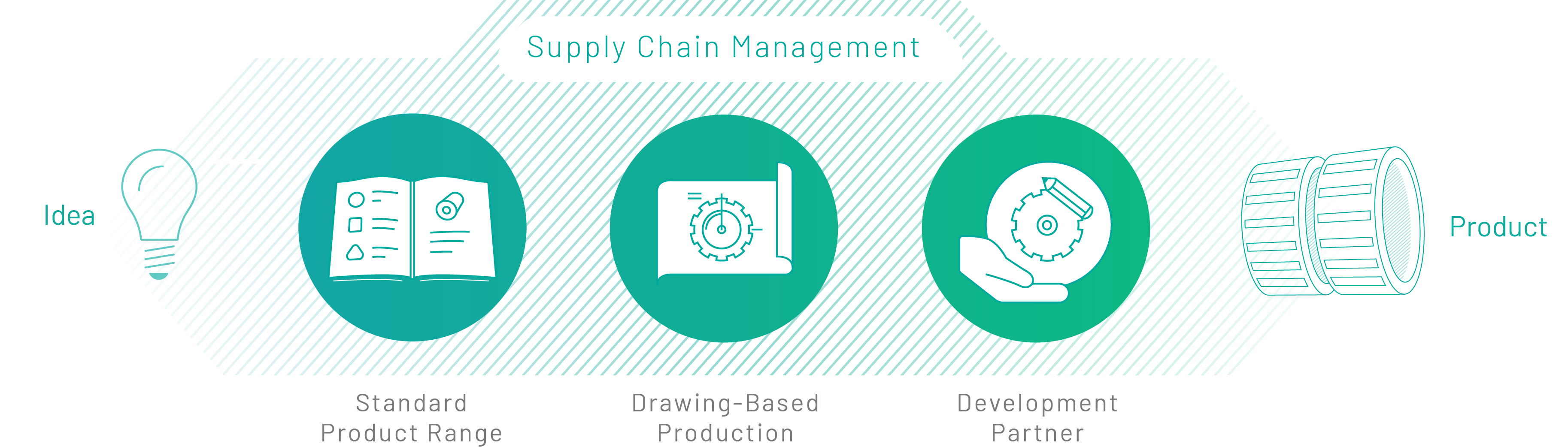

In our standard range of rubber, silicone and plastic products, customers can find what they are looking for from trial and small series to large series – with high availability and fast delivery.

As a technology-independent manufacturing specialist in both elastomers and plastics, we offer our customers the best solution based on their drawings and specific applications. The basis for this is provided by our broad-based internal production and our specialized external suppliers.

As development partners, our engineers and process specialists work closely with our customers to design individual and customized products and materials. Our own rubber mixing plant is at the center of our material development and testing. Our benchmark is to always meet the highest quality standards – starting with development and project management, through professionally organized series production ramp-up, to reliable and customer-specific supply.

Certified to ISO

Euro turnover 2023

Since

Employees from 25 nations

Sales locations

Customers

Get an insight into our company and the world of the unique materials rubber and plastics. In addition to our DIN EN ISO 9001 and 14001 certificates, you will also find interesting customer projects and our chemical stability list for selected elastomers and thermoplastics.

You can also keep up to date via our JÄGER Business Blog or LinkedIn.

Why JÄGER?

Companies that rely on our expertise

Jäger Gummi und Kunststoff GmbH

Lohweg 1

30559 Hannover

Tel. +49 511 – 53580

Fax +49 511 – 553394

info@jaeger-gk.de

Management:

Dr.-Ing. Andreas Jäger und

Julius Jäger

Hanover Register Court HRB 59798

DE 813 314 161

Sie haben noch Fragen oder benötigen weitere Informationen?

Kein Problem!

Füllen Sie einfach unser Kontaktformular aus. Unser Team wird sich umgehend mit Ihnen in Verbindung setzen, um alle Ihre Anliegen zu klären.